Keeping crudes flowing

To meet shifting demand patterns, the global movement of crudes is changing, making it increasingly important to optimise logistics costs to reduce operating expenses. Daniel Deneen, Infineum Business Development Manager, explains to Infineum Insight how the growing use of unconventional crudes is introducing additional challenges to upstream, midstream and downstream markets.

The North American production of shale and oil sands crudes has surged to new highs in 2018 – a trend that looks likely to continue as the global appetite for energy continues to grow. While the increased use of these advantaged crudes adds value at the refinery, it also brings additional downstream, midstream and upstream complexity.

The efficient transport and conversion of these non-conventional, inherently variable crudes is of growing importance to producers and refiners. However, issues persist – for example:

- Wax and/or asphaltene deposition can lead to flow assurance problems during oil production and transportation.

- Asphaltene instability (or drop-out) can cause issues in blending operations at the refinery and contribute to fouling of heat exchangers.

Producers, traders and refiners are looking for cost effective solutions to help resolve several key issues including:

- Wax and asphaltene deposit control

- Viscosity and pour point management in heavy/medium crudes

- Refinery heat exchanger fouling

Improving crude transportation and delivery

One of the key challenges in the transportation of crudes is reducing ‘remain-on-board’ (ROB) – to ensure as close to the full amount of product that was shipped is delivered to the customer.

A new, high-throughput bench test has been developed by Infineum to simulate crude storage in railcars, ships and crude storage tanks, which has demonstrated a good correlation with larger scale tests. The test, which mimics ROB issues, provides information relating to wax settling and how ‘pumpable’ the test crude is at low temperatures.

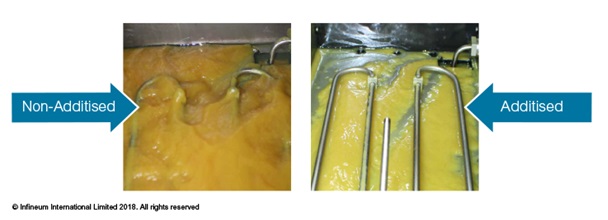

Additives have been identified that change the morphology of the remaining wax, such that it is ‘light and fluffy’. This keeps the wax more mobile, ensuring it adheres less to the ship or pipeline walls – ultimately reducing ROB losses.

Wax crystal modification in the treated vessel means reduced ROB and easier cleaning

Wax and Asphaltene deposition

Asphaltenes are high molecular weight materials found in crude oil, which can agglomerate to form deposits. Along with asphaltene deposits, wax crystals may also form in crudes, which can grow quickly to create gels.

Deposition of contaminants and wax in storage tanks and transport vessels can reduce delivered crude volumes, increase cleaning and maintenance costs, increase pumping out times and necessitate the use of heated storage. Wax deposits can also plug gathering lines and increase corrosion in transmission lines, thereby increasing pigging and maintenance costs.

In crude production, asphaltene and wax deposits inhibit flow assurance in pipelines and risers – reducing production yield.

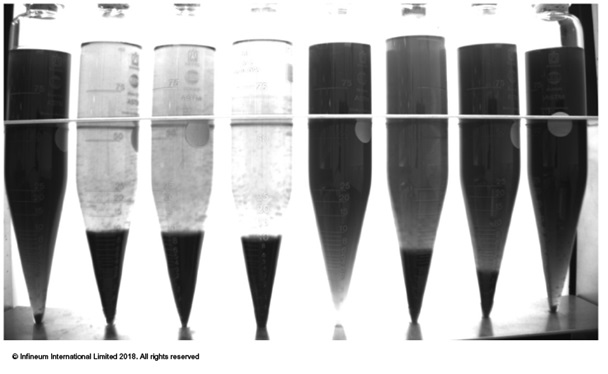

Asphaltene dispersive properties have been assessed and settling rates determined

By understanding wax formation and how additives respond in crude oils, Infineum can assess the best morphology to keep wax mobile and how to prevent it from depositing in upstream and midstream assets. Techniques including cross polarised microscopy, cold finger analysis and proprietary bench tests have been carried out on a wide number of crudes so that the performance of candidate additives can be carefully matched to the crudes.

Heat exchanger fouling

Asphaltene fouling of the refinery heat exchangers can erode profits by increasing maintenance costs and by reducing throughput. To tackle this issue, Infineum has tested the intrinsic stability and asphaltene dispersive properties of crude oils. In addition, a proprietary thermal deposition test has been developed, which uses carbon steel rods to assess thermo-oxidation under various conditions. Through our fundamental research, we have identified several additives that are effective in reducing thermal fouling.

Additives have been identified that reduce deposit formation in thermal deposition testing

The use of these high performing, thermo-responsive additives can help to prevent refinery heat exchanger fouling. This can help to decrease the energy required for crude distillation, lower heat exchanger maintenance costs and enable a higher crude throughput.

Summary

Crude slate variability and the pressure to improve industry economics are continuing to create technical challenges in oil production, transportation and refining.

Additives have been identified that can help to address the complexities introduced by the growing use of unconventional crudes. By relating additive performance to the crude characteristics, robust solutions have been developed that keep wax mobile and improve asphaltene deposit control.

By collaborating with universities and industry bodies, Infineum is developing new additive solutions, while broadening its fundamental understanding in the areas of wax management, asphaltene control and refinery anti-foulants. Our active research programme will ensure additive solutions continue to make important contributions to the efficient production, handling and transportation of crude oil.

To download this article in full, visit the downloads section of the Multisol website. For more information on Multisol’s ongoing collaboration with refineries throughout Europe and market-leading range of Infineum products, click here.